Manufactur standard China Heat Insulation Thermal Insulation IR Rejection Infrared Blocking Plastic Masterbatch

Our commission should be to serve our end users and purchasers with finest top quality and competitive portable digital products and solutions for Manufactur standard China Heat Insulation Thermal Insulation IR Rejection Infrared Blocking Plastic Masterbatch, Welcome to visit our company and factory. Please feel free to get in touch with us if you need any further assistance.

Our commission should be to serve our end users and purchasers with finest top quality and competitive portable digital products and solutions for China Heat Insulation, Thermal Insulation, Now we have a specialist sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalised service and unique goods.

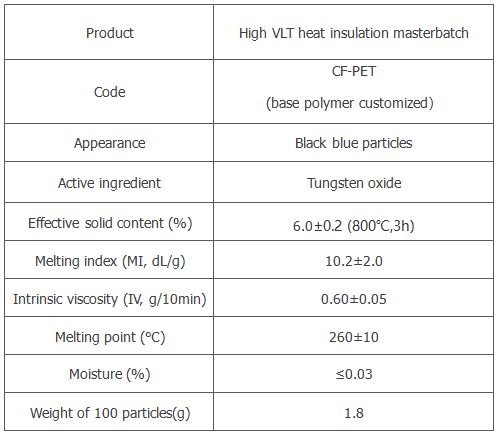

Parameter:

Feature:

-The film made by the masterbatch has high transparency, VLT 60-75%, haze<0.5%;

-Good heat insulation performance, infrared blocking rate ≥99%;

- Strong weather resistance, no fading, performance no degradation;

- Good dispersibility and compatibility, stable performance;

-Environment friendly, no toxic and harmful substances.

Application:

It is used to develop films or sheets, that has functions of heat insulation, anti-infrared and anti-ultraviolet, such as solar window films, PC sunlight sheets, agricultural film, or other fields that has the requirement of anti-infrared.

-Solar window film: Through the process of biaxially oriented tensile, BOPET IR film is got, with that heat insulation window film is obtained without coating heat insulation layer;

-PC sunlight sheet: Through co-extrusion process, energy-saving heat insulation sheet is made easily.

-Agricultural greenhouse film: Through co-extrusion process, heat insulation and anti-UV greenhouse film is produced, with that vegetables output is increased significantly by reducing transpiration of the plant.

Usage:

It is suggested to be used together with Huzheng low VLT masterbatch S-PET and carbon crystal masterbatch T-PET. According to the required optical parameters and specifications, refer to the following dosage table, mix it with common plastic slices as the recommended dosage, produce as the original process. Various base materials can be provided, such as PET, PE, PC, PMMA, PVC etc.

Packing:

Packing: 25 kg/bag.

Storage: in a cool, dry place.