ODM Supplier China Nano Tungsten Trioxide Infrared Absorber Oil-Based Heat-Insulation Liquid

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for ODM Supplier China Nano Tungsten Trioxide Infrared Absorber Oil-Based Heat-Insulation Liquid, Trust us, you might discover a far better solution on car parts industry.

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for China Tungsten Oxide, Infrared Absorber Liquid, We’re looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

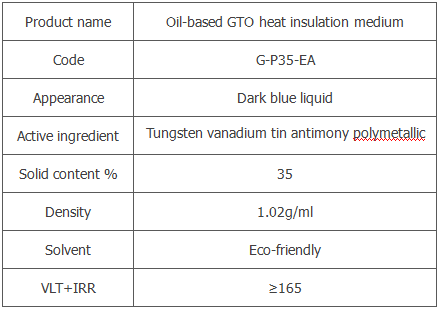

Parameter:

Feature:

-High heat insulation, good transparency, when infrared blocking rate 99%, visible light transmittance can reach more than 70%;

-It has good universality, can be matched with most resin such as acrylic resin and UV resin;

-We owns a number of independent intellectual property rights on it, therefore advantages in technology and price;

-Strong weather resistance, QUV 5000 h, no attenuation in performance, no change in color;

-Safe and reliable, free of toxic and harmful substances such as halogen, heavy metals.

Application:

It is used to make high performance insulation window film, which can be used for automobile and building glass to get heat insulation, energy saving, improving comfort, or it is used in other fields with the requirement of heat insulation or anti-infrared.

Usage:

Note: Small sample test with resin is necessary before use.

Step 1: Taking out the below material by weight ratio: GTO solution: diluting agent: PSA resin=1.5:4:4. Adjusting the GTO dosage according to the parameter requested (7099) with testing machine with 950nm.

Diluting agent: the mixing of EA:TOL =1:1

Step 2: Mixing. Mix them one by one: adding GTO solution — adding diluting agent — stirring — adding PSA resin while stirring. Stirring for about 40min after adding PSA, and then filtering the mixture with 1um filter cloth.

Step 3: Choosing PET basic film. Choose the PET basic film with VLT over 90% and corona layer.

Step 4: Coating. Coat them (the mixture in step 2) on the PET film by wet film coating machine.

Step 5: Drying, laminating. Controlling the coating thickness between 6-8um, drying Temperature: 85~120 deg.

Notes:

1. G-P35-EA can’t be added for reverse adjustment during the batching process or after the ingredients are finished.

2. In every mixing, the order of addition must be abided strictly, especially that the mixing tank can not be used without cleaning thoroughly, even a small amount of residual working fluid will lead to serious problems such as graininess precipitation.

3. When cleaning the pipeline and related equipment, the special diluent has to be used.

Notes:

1. Keep sealed and store in a cool place, make the label clear to avoid misusing.

2. Keep far from the fire, at the place where children can’t reach;

3. Ventilate well and prohibit the fire strictly;

4. Wear PPE, such as protective clothing, protective gloves and goggles;

5. Prohibit contacting with the mouth, eyes and skin, in case of any contact, flush with large amount of water immediately, call a doctor if necessary.

Packing:

Packing:1kg/bottle; 20kg/barrel.

Storage: in a cool, dry place, avoiding sun exposure.