Ukusebenza Okuphezulu Kokufakwa Kwengilazi Yokushisa Kokushisa

Ipharamitha Yomkhiqizo

| Ikhodi | I-AMS-99V | Ukugqoka ukumelana | >4000 izikhathi |

| Isakhi | ongashadile | Isikhathi sokuhlanza ubuso | 20 ~ 60 min (kuye ngokuthi izinga lokushisa elizungezile) |

| Ukubukeka | Uketshezi oluluhlaza okwesibhakabhaka omnyama | Isikhathi sokuphumula esinzima | Izinsuku ezingu-7 |

| Okuqukethwe okuqinile% | 29±1 | Ukungafihli | 80% |

| Ukuminyana | 0.95g/ml | Izinga lokuvinjwa kwe-infrared% | >90%(1400nm) |

| Indlela yokumboza | Isipontshi enamathela | Izinga lokuvimbela i-Ultraviolet% | 99% |

| Ubukhulu befilimu eyomile | 3 ~ 4m | I-coefficient yomthunzi | 0.49 |

| Ukuqina kobuso bokunamathela | 8H(Mitsubishi penseli) | T umehluko(lab) | 10 ~ 18℃ |

| Ukunamathela | Ibanga lesi-0 | Ukonga amandla | 28~32% |

Isici soMkhiqizo

-Uhlelo lokusebenza olulula, lusetshenziswe ngokuthanda nangokukhululekile, ikhono elihle kakhulu lokulinganisa;

-Ukukhanya okuphezulu, akuthinti izidingo zokubonakala nokukhanyisa, ukufakwa kokushisa okubalulekile nokonga amandla;

-Ukumelana nesimo sezulu esinamandla, ngemuva kokuhlolwa kwamahora we-QUV 5000, akukho shintsho ekugqokeni, impilo yenkonzo yeminyaka eyi-10;

- Ubulukhuni obuphezulu bobuso, ukumelana nokugqokwa okuhle, ukunamathela ebangeni lesi-0.

Inkambu yohlelo lokusebenza

Isetshenziselwa ukwahlukanisa ukushisa nokonga amandla engilazi yokwakha, njengezakhiwo zebhizinisi, amahhotela, izindawo zokudlela ezisezingeni eliphezulu, ingilazi ye-zenith, indawo yokuhlala, njll.

Isetshenziselwa ingilazi yezimboni enezidingo zokuvikela imisebe ye-infrared kanye ne-ultraviolet.

Indlela Yokufaka Isicelo

Sicela ufunde inqubo yokufaka isicelo elandelayo, izindlela nezindlela zokuphepha, bese ubuka ividiyo yohlelo lokusebenza ngaphambi kokuyisebenzisa.Ukushisa kwe-Ambient ku-15 ~ 40℃, umswakama ongaphansi kuka-80%.Alukho uthuli nezinye izici ezingathandeki.

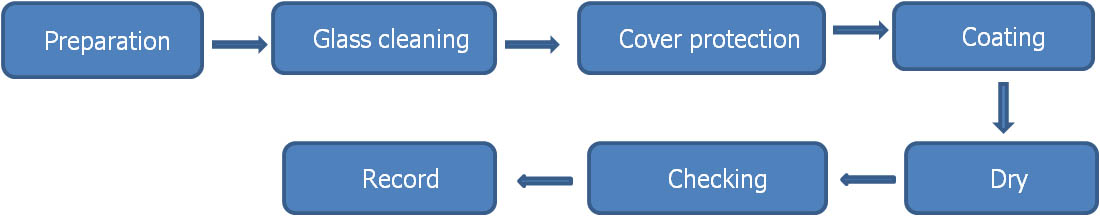

1. Inqubo Yokufaka Isicelo

2. Indlela Yokufaka Isicelo

Isinyathelo 1: Lungiselela amathuluzi nezinto zokwakha kanje:

-Amanzi ahlanzekile: asetshenziselwa ukuhlanza kokuqala kwendawo yengilazi kanye nenhloso yokusebenzisa amanzi ahlanzekile ukunciphisa ukungcola okusha ohlelweni lokuhlanza ingilazi.

-I-ejenti yokuhlanza: ingilazi yokuhlanza nge-ejenti yokuhlanza ekhethekile enekhono eliqinile lokuqeda ukungcola, esebenza njengokuhlanza ingilazi yokuqala.

-I-ethanol engenamanzi: I-90% yotshwala bezimboni iyadingeka ukuhlanza ingilazi okwesibili ukuze kukhishwe i-ejenti yokuhlanza esele ebusweni bengilazi.

-I-Plastic strip kanye nefilimu evikelayo: ifreyimu yengilazi ivikelwe yi-plastic strip ngesikhathi sokwakhiwa ukuze kuqinisekiswe ukuthi indawo yokuxhumana phakathi kwendawo yefilimu kanye nohlaka lwengilazi ihlelekile.Ifilimu yokuzivikela inamathele emaphethelweni angaphansi kwefreyimu yeglasi ukuze kugwenywe ukungcoliswa kodonga kanye nomhlabathi ngesikhathi senqubo yokumboza.

-I-Coating kanye ne-diluent: i-solvent-based coatings ingahlukaniswa ibe yizinto eziyinhloko kanye ne-diluent, futhi inani elihambisanayo le-diluent kufanele lengezwe ngokuvumelana nezinga lokushisa losuku olufanayo ukuze uthole ibhulashi elingcono.Uma izinga lokushisa lingaphezu kuka-30 ℃, i-diluent (5% yesisindo sempahla eyinhloko) kufanele yengezwe, qiniseka ukuthi ufaka isinciphisi ezintweni eziyinhloko futhi uxube ngokulinganayo ngaphambi kokufaka.

-Inkomishi yokulinganisa ne-dropper, ipuleti lokuphakelayo: isetshenziselwa ukukala izincibilikisi, nokusebenzisa inani elincane le-dropper ukuze kuzuzwe izingxenye ezinembile, futhi ekugcineni uthele ethreyini.

Iphepha elingelukiwe namathawula, isipontshi Sula: isipontshi sula sicwiliswe ngenani elifanele le-ejenti yokuhlanza, ngendlela evunguzayo yokusula ubuso bengilazi, ngethawula ukusula i-ejenti yokuhlanza esele, kusetshenziselwa iphepha elingalukiwe. hlanza indawo yengilazi ngesikhathi sokuhlanza i-ethanol yesibili engasebenzi, bese usula ithreyi nenkomishi yokulinganisa ngephepha elingalukiwe ngesikhathi esifanayo isikhathi ngasinye lapho kuthathwa impahla.

-Ithuluzi le-Scraper: namathisela umucu wesipontshi se-nano ethuluzini le-scraper, bese uwucwilisa embotsheni bese uwuxubha.

Qaphela:I-ethanol engena-hydrous namanzi ahlanzekile adinga ukuhlinzekwa ngamakhasimende ngenxa yezinto zokuhamba ezingalungile.

Isinyathelo sesi-2: Hlanza ingilazi.Ingilazi ihlanzwa kabili nge-ejenti yokuhlanza ekhethekile kanye notshwala be-ethyl obuphelele.

I-ejenti yokuhlanza iqala ikhishelwe esipontshini, bese kufafazwa inani elincane lamanzi ahlanzekile esipontshini, bese isipontshi sesulwa phezu kwengilazi ngesipontshi esicwiliswe nge-ejenti yokuhlanza kuze kube yilapho ingilazi isiphelile. akukho ibala elinamafutha, bese i-ejenti yokuhlanza isuswa ngethawula elihlanzekile;(Qaphela: Uma ithawula lisulwa, ikhoneni kufanele ligqanyiswe, ngoba ikhoneni akulula ukuyihlanza ngemva kokuba i-adhesive tape inamathiselwe. I-ejenti yokuhlanza i-erase ingasetshenziswa ngethawula elifanayo, kodwa akunakwenzeka ukusebenzisa i-adhesive tape. ithawula elingcoliswe ukunamathela nothuli).Hlanza ingilazi nge-ethanol engenamanzi okwesibili;Fafaza ingilazi ngenani elifanele le-ethanol engenamanzi, bese usula ingilazi ngephepha elingalukiwe kuze kube yilapho kungabikho uthuli olubonakalayo.I-ethanol engenamanzi ngeke isakwazi ukuthinta ingilazi ngemva kokuba isulwe yahlanzeka.

(Qaphela:Ikhona yilona elithambekele kakhulu ekungcoleni okuyinsalela, gxila ekuhlanzeni nasekusuleni)

Isinyathelo sesi-3: ukuvikelwa komngcele.

Ukuze ugweme ukuthinta ngokuzenzakalelayo uhlaka lwengilazi ngesikhathi senqubo yokumboza, futhi ugcine imiphetho yengilazi eboshwe kahle, kuyadingeka ukusebenzisa ibha yepulasitiki ukumboza ingilazi ngokuhambisana nemithethonqubo, ukuqinisekisa ukuthi isembozo siqinile. ngaphambi kokufaka inqubo elandelayo.Kubalulekile ukwenza isiqiniseko sokuthi inhlanganisela ye-coating kanye ne-plastic strip icocekile futhi ihlelekile, futhi kufanele kube nohlangothi olulodwa olunamathiselwe engilazini uma unamathisele, ikakhulukazi ekhoneni, ukuze kuqinisekiswe ukuthi umugqa uhlanzekile futhi muhle.

Isinyathelo sesi-4: Ukugqoka okuhlelekile (qiniseka ukuthi ingilazi eyomile iqala ukugcotshwa ngemva kokuhlanza).

- Isisindo se-Coating kanye nokulungiselela:

Hlanza ithreyi nenkomishi yokulinganisa ngotshwala be-ethyl obuphelele nephepha elingalukiwe.

Thela inani elihambisanayo elihlanganisiwe enkomishini yokulinganisa ngokwezinga lika-20 g/m2.Uma izinga lokushisa lomoya lingaphezulu kuka-30 ℃, i-diluent enesisindo esingu-5% wesisindo sempahla eyinhloko iyadingeka ukuthi ifakwe ezintweni eziyinhloko futhi ixutshwe.Indlela yokuxuba ihlanganisa lezi zinyathelo ezilandelayo: ukwengeza inhlanzi ekulinganiseni ngokwesilinganiso, bese uthela inkomishi yokulinganisa kwenye inkomishi yokulinganisa egcwele ukunamathela bese unyakaza kahle.

Ifomula yomthamo wokumboza: ubude bengilazi(m) × ububanzi(m) × 20g/m2

(Qaphela:hlanza ithreyi nenkomishi yokulinganisa nge-ethanol engenamanzi nephepha elingalukiwe ngaphambi nangemva kokusetshenziswa ngakunye.)

-Ukugqoka okuhlelekile.Ngokwendawo yengilazi yokwakha ngokusho kwe-20g / m2, enesisindo sokugqoka okudingekayo, futhi uthele konke ku-feed plate;Bese usebenzisa isipontshi se-nano esimuncwe inani elifanele lokumboza, bese uklwebha phezu kwengilazi ngokulinganayo ukusuka kwesokudla kuye kwesokunxele, bese ukusuka phansi kuya phezulu ukuze uqinisekise ukuthi okokunamathela kuhlanganiswe ngokulinganayo kulo lonke ucezu lwengilazi.Ekugcineni, kusukela ohlangothini olulodwa, ifilimu iphelile kusukela phansi kuya phezulu ukuze kuqinisekiswe ukuthi ifilimu ayinamabhamuza, ayikho izimpawu zokugeleza kanye nomfaniswano ebusweni beglasi.

(Qaphela:Inqubo yokumboza kufanele ibe ijubane elifanayo, amandla afanayo futhi ungaqhubeki kakhulu;kusuka emazingeni ahlukene ukuze ubuke okwengeziwe, noma ngabe kukhona into engalingani;Ngemva kokuqeda, uma kutholakala iphutha, ithuluzi lokukrwela kufanele lisetshenziswe ngesikhathi esifushane ukushwiba izikhathi ezimbalwa endaweni enesici, bese ulikhuhla liye phezulu naphansi kabili ngokushesha, bese liphinda liqeda.Inombolo encane yamaphuzu e-crystal ingase ibonakale ebusweni ngemva kokuqedwa kokugqoka, kodwa asikho isidingo sokukhathazeka ukuthi, njengoba amaphuzu ekristalu azonyamalala phakathi namahora angu-24.)

Isinyathelo sesi-5: Ukwelapha okujwayelekile kwezinga lokushisa

Ngemuva kwemizuzu engu-20 ~ 60 (kuncike ekushiseni okuzungezile), indawo yokumboza iqiniswa ngokuyisisekelo.Phakathi nehora lesikhathi sokuphulukisa, akukho lutho olungathinta ukunamathela;Phakathi nesonto, akukho nto ebukhali engathinta i-coating.

Isinyathelo sesi-6: Iyahlola

Ngemuva kokuthi ubuso be-coating bomile futhi buqiniswe, susa izinto ezifana ne-adhesive tape yephepha, ifilimu yokuzivikela, njll ngokucophelela.

Isinyathelo sesi-7: Rekhoda bese ugcwalisa ifomu

Rekhoda izinga lokushisa le-ambient, umswakama, izinga lokushisa elingaphezulu nokunye, wenze umsebenzi wokuqeda kahle.

3. Ukuqapha

-Enqubweni yokusetshenziswa kwe-coating, isinyathelo ngasinye sokususa kufanele sisheshe, ngangokunokwenzeka ukunciphisa isikhathi sokuxhumana phakathi kokugqoka nomoya;

-Izinga lokushisa le-ambient lizoba phakathi kuka-15 no-40℃, futhi umswakama akufanele ube ngaphezu kuka-80% futhi akufanele kube namaconsi amanzi phezu kwengilazi;

-Ilangabi elivulekile noma inhlansi ayivunyelwe eduze, futhi ukubhema akuvunyelwe;

-Igcinwe endaweni epholile, enomoya omuhle, gwema ukuchayeka elangeni, hhayi eduze nokushisa, imililo, imithombo yamandla;

- Gcina kude nezingane, futhi ugweme ukuthintana nesikhumba noma amehlo;

- Uma uthintana namehlo, geza ngamanzi amaningi, shayela udokotela.

-Ungaweli kwezinye izindawo ukuze ugweme ukugqwala, uma uthintana, sula nge-ethanol engenamanzi ngokushesha okukhulu.

*Umshwana wokuzihlangula

Abathengisi, abasebenzisi, ezokuthutha nabagcinisi bomkhiqizo (okubizwa ngabo ndawonye njengabasebenzisi) bomkhiqizo badinga ukuthola inguqulo ephumelelayo, yenguqulo yakamuva yokucaciswa kobuchwepheshe bokuphepha kwamakhemikhali (MSDS) eziteshini ezisemthethweni ze-Shanghai Huzheng Nanotechnology Co., Ltd. ngicela uyifunde ngokucophelela.Kuphakanyiswa ukuthi abasebenzisi kufanele bathole ukuqeqeshwa kochwepheshe.

Iphakheji &Isitoreji

Isitoreji: Gcina uvaliwe ngaphansi kuka-40 ℃, kude nokushisa, umlilo, nomthombo wamandla, impilo yeshelufu 6 izinyanga